1. Development trends of chemical grouting injection

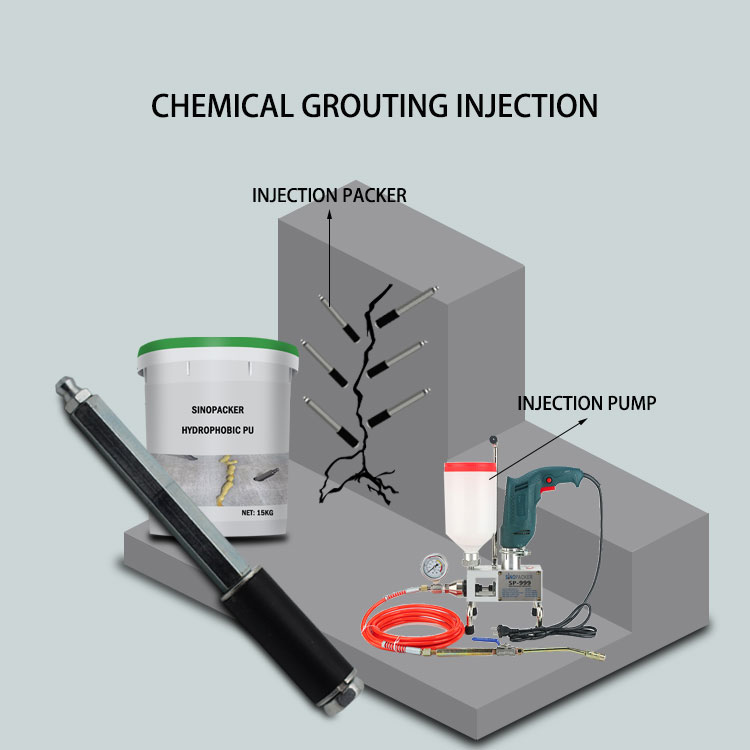

Chemical grouting is a concrete repair technology with liquid materials into concrete cracks through injection pump equipment and injection packer. Chemical grouting is an engineering technology that combines chemistry and engineering and uses chemical science and chemical slurries to solve foundation and concrete defects (reinforcement, anti-seepage and plugging) to ensure the smooth progress of the project or to improve the quality of the project.

Chemical grouting was originally developed to meet the needs of foundation treatment and mining industry development. Its reliability has been recognized and has been widely used for more than 80 years. Chemical grouting technology is mainly manifested in the following aspects.

1. Chemical grouting has developed from zero and has become an indispensable part of modern engineering technology.

2. Commonly used chemical grouting materials, such as epoxy, methane, acrylic, acrylate, acidic and alkaline sodium silicate, water-soluble, water-insoluble and elastic polyurethane, urea-formaldehyde resin, chrome lignin, etc.

3. The research and development of chemical grouting equipment has basically been able to adapt to and meet the requirements of chemical grouting projects, such as chemical grouting pumps, injection packer, and various sealing materials, etc.

4. Chemical grouting technology has been promoted and applied in four major sectors: hydropower (dams, embankments, reservoirs, power stations), construction (above ground, underground, civil air defense), transportation (roads, railways, tunnels, bridges, ports, airports) and mining.

5. The application of chemical grouting technology has solved many engineering problems and achieved good benefits. Water conservancy projects such as the Three Gorges Dam and Gezhouba are typical examples of using chemical grouting technology to solve some engineering and technical problems.

6. There are also some breakthroughs and innovations in chemical grouting theory, such as the calculation theory of grout diffusion radius, grout wet surface bonding theory, antagonism theory to reduce grout toxicity, grout imbibition theory, etc.

7. Chemical grouting technology publications have achieved a bumper harvest. Many scientific and technological journals around the world, including Journal of Hydraulic Engineering, Journal of Water Conservancy and Hydropower Technology, Journal of Geotechnical Engineering, and Journal of Rock Mechanics and Engineering, have selected research papers on chemical grouting.

The above achievements are enough to illustrate the progress and development level of chemical grouting technology. In addition, engineering and scientific personnel studying chemical grouting technology have established the Chemical Grouting Society, which has held many academic exchanges. These academic activities have played a good role in promoting the research and development of chemical grouting materials and the development of chemical grouting technology.

2 Prospects of chemical grouting technology

Chemical grouting technology should continue to develop more dynamically based on the past 80 years. The development and application of chemical grouting materials that are pollution-free, durable, adaptable to various requirements of various projects, and low-priced; the research, improvement and improvement of chemical grouting technology; the finalization, serialization and complete sets of chemical grouting equipment and equipment production , standardization, environmental protection, and continuous improvement and improvement of product quality are bound to be its development directions.

2.1 Development of pollution-free chemical grouting materials

1. Development of non-toxic catalysts. Epoxy resin grout has high bonding strength and good stability, so it is the most commonly used chemical grouting material for consolidation grouting. The toxic and side effects of this material mainly come from the curing agent and solvent used. In the past, amine curing of epoxy grout Research on reducing the toxicity of epoxy slurries has achieved some results. A batch of modified amine curing agents with low toxic and side effects have played a good role in the promotion and application of epoxy slurries. We should continue to work in this direction in the future.

2. Development of solvent-free slurry. Epoxy resins generally have high viscosity, and organic solvents are generally added to manufactured grouting materials. However, many organic solvents not only smell bad, but also have toxic side effects (such as furfural), and often cause environmental problems after being added. Therefore, while people are studying epoxy curing agents without toxic side effects, they are also developing solvent-free epoxy slurries. Research on solvent-free epoxy grouting materials will benefit from the development of the epoxy resin industry. The viscosity of low-molecular-weight epoxy resins produced by some chemical plants is only 20-25mPa.s., which will have a negative impact on future solvent-free epoxy grouting materials. The development has opened up better prospects. In addition, the development of acrylate and other resins into solvent-free slurries has shown a better prospect and is worth exploring.

3. Development of chemical grouting materials using water as medium. Water is used as the medium without organic solvents, which is very beneficial to the pollution-free chemical grouting materials. The water-soluble polyurethane slurry has been developed in the past. In the future, we should open our eyes to water-soluble slurries. I believe that in the organic or inorganic water-soluble slurry Material development and application will show ideal progress.

4. Research on the modification of some existing chemical grouting materials. In 1974, Japan announced the ban on acrylonitrile because the use of acrylic grouting materials with good impermeability polluted water quality and caused drinking water poisoning. After that, acrylate slurry with similar properties to acrylic coagulation was developed, but its main component, magnesium acrylate, still had certain toxic side effects. However, scientific and technological workers used the principle of antagonism to add calcium salt and an appropriate amount of certain certain substances to the acrylate slurry. Antagonist, but its toxic and side effects are reduced to only 1% of acrylonitrile, making it an actually non-toxic grout material. This example shows that we can explore ways to transform some of our existing chemical grouting materials to reduce toxicity and achieve a tolerable level. Use standards.

2.2 Development of chemical grout materials suitable for various engineering requirements

1. Research on new high-moisture and high-permeability grouting materials. Although we currently have some high-permeability chemical grouting materials that have solved many engineering problems, most of the solvents and curing agents used have toxic side effects and are not suitable for environmental standards. It is still necessary to explore new high-moisture, high-permeability, non-toxic and side-effect grouting materials for the treatment of interlayer and concrete micro-cracks. This largely depends on the research and improvement of surfactant and reactive diluent systems.

2. Development of elastic grouting materials. Elastic grouting materials are needed for water sealing of expansion joints and reinforcing grouting of concrete living joints and deformation joints. Although there have been some developments in the past, the quality must not be high enough. In the future, in addition to strengthening the existing elastic epoxy and elastic polyurethane In addition to research on improving the quality of slurry materials and eliminating toxic and side effects, it is more important to strengthen the development and research of curing agents that can impart elasticity to epoxy resins to meet the urgent needs of construction projects.

3. Development of fast setting chemical grouting materials. This refers to the development of slurry materials with low slurry viscosity, excellent cured product properties, and curing time that can be controlled within tens of minutes or hours. The use of low-viscosity epoxy resin or new reactive diluents and the development and application of new epoxy curing agents that can promote rapid curing of epoxy resin should be able to solve this problem.

2.3 Development of durable chemical grouting materials

The concept of durability is broad, including water resistance, acid and alkali resistance, weather resistance, UV resistance, freeze-thaw resistance, dry-wet cycle resistance, abrasion resistance, resistance to microbial action (mildew), etc. The development of durable chemical grouting materials can be as follows:

1. Through the grafting or embedded copolymerization of synthetic resins, the resin used in chemical grouting materials has some of the durability characteristics we require.

2. Pay attention to the research on interpenetrating network composite chemical grouting materials. For example, the existing MU solvent-free slurry is a composite of acrylate-polyurethane, and the PU/EP underwater grouting material is a composite of polyurethane-epoxy resin. They are all interpenetrating network composite grouting materials. Due to the composite structure of the two types of resins and their interpenetrating network structure, this gives them superior properties beyond any single resin component and is worthy of in-depth study.

3. Add nanomaterials to modify the existing chemical grouting materials. Epoxy resin modified with nanomaterials will improve the performance of epoxy grout in many aspects, including durability.

2.4 Development of inexpensive chemical grouting materials

1. Modification of water glass chemical grouting materials. Water glass grout is the earliest chemical grouting material used in the history of chemical grouting, and it is also one of the most widely used chemical grouting materials at present. The reason for this is that in addition to the advantages of the slurry, such as non-toxicity, low viscosity, and good pourability, the low price of the slurry is an important factor. The disadvantages of this slurry are that the gel time adjustment is not stable enough, the gel strength is very low, the gel stability is poor, and metal ions are easy to dissolve, etc. It is now mostly used in temporary or semi-permanent projects. Therefore, future modification work should focus on improving strength and durability. Adding certain active substances for modification is a direction worth exploring.

2. Development of harmless pulp materials for pulp waste liquid. The price of chemical grouting materials made from pulp waste liquid is relatively low. By adding chromium catalysts to the waste liquid, the pulp material now called chromium lignin can be produced. Because the hexavalent chromium ions in the chromium catalyst are toxic, the pulp material No one dared to use it. Therefore, a variety of high-strength lignin pulp materials without chromium catalysts were subsequently developed. In the future, research on improving their performance should be carried out in order to promote their application.

2.5 Improvement, improvement and innovation of chemical grouting technology

There have been studies on the summary, improvement and improvement of chemical irrigation technology. It has been described before that in the past 80 years, chemical grouting technology has been applied to a large number of construction projects, including hydropower, etc. There are many typical experiences of using chemical grouting to solve engineering problems, some of which have been preliminary summarized, such as composite grouting technology; some It has yet to be summarized, such as the closed transmission, automatic recording, centralized management and real-time monitoring technology of chemical irrigation. Regardless of whether there has been any summary in the past, the existing chemical irrigation technology requires experts, scholars and experienced personnel engaged in chemical irrigation technology research. Engineering and technical personnel combine to improve and innovate on the basis of summarizing practical experience.

2.6 Development of chemical grouting pump equipment and accesorries

1. Serialization, complete sets and standardization of high-performance chemical grouting pumps. High-performance chemical grouting pumps are the main equipment for chemical grouting operations. Nowadays, many research institutes and small companies can research and develop them, but they can only produce in small batches or trial production. In the future, production should be fixed-point and finalized, and should be developed in the direction of serialization, complete sets, and standardization of products to facilitate the promotion and application of chemical irrigation technology.

2. Development of chemical grouting self-recording instrument. The development of chemical grouting self-recording instrument can effectively avoid some errors that inevitably occur in manual recording, will play a good monitoring role in improving the quality of chemical grouting in concealed projects, and establish chemical grouting data analysis on a reliable basis. . The chemical grouting self-recording instrument is different from the existing cement grouting self-recording instrument in terms of technical principles. At present, there are several sets of development plans, but no samples have been released yet. It is very necessary to speed up the development pace to cope with engineering.

3. Development of closed chemical grouting materials transmission equipment. Some of the equipment that has been developed must meet environmental standards to ensure safe production.

4. Research on improving the quality of existing products. There is a lot of work to be done to improve the processing accuracy and quality of some chemical grouting equipment and instruments currently produced.

2.7 Formulation of chemical grouting industry standards

The construction of chemical grouting materials has hidden characteristics. If the construction is carried out in different ways, many problems will inevitably occur, and even cause hidden dangers in the project, which deserves our high vigilance. However, there is still no industry standard and chemical irrigation construction procedures and specifications. This is a very abnormal phenomenon and should be formulated immediately.

Industry standards and specifications are developed to ensure the consistency of product or service quality, improve efficiency and safety, and promote the sustainable development of the industry.

1. Research and research. It is important to conduct adequate research and investigation into the chemical grouting industry before formulating industry standards and regulations. This includes collecting existing standards and normative documents in the industry, relevant laws and regulations, and international standards in similar fields. Understanding existing situations can help us avoid duplication of efforts and draw on best practices.

2. Problem analysis. By gathering information we can identify current problems and needs. Questionnaires, symposiums, etc. can be conducted to collect opinions and suggestions from people and users in the industry. Organize and analyze the opinions of different groups to find common problems and improve them.

3. Written step by step. According to the overall framework of the first draft, the specific content is gradually filled in. Articles can be written in a modular and hierarchical manner. It is recommended to start with the key points and core issues to ensure the accuracy and detail of the relevant content.

4. Revision and review. After formulating the first draft, opinions should be solicited from relevant units, chemical grouting company enterprises and experts and revised repeatedly. This helps increase communication and coordination among different stakeholders and gain wider acceptance in standards and specifications.

2.8 Research of chemical grouting theory

It is difficult to simulate chemical grouting in the laboratory. The theoretical research on chemical grouting has always been a weak link in the development of chemical grouting technology and has been difficult. In the past, chemical grouting construction and the determination of many construction parameters relied on experience and lacked theoretical guidance. In order to promote chemical grouting technology With the scientific promotion and application in many engineering fields, it is necessary to strengthen the research and exploration of grouting theory in the laboratory in the future.

1. Conduct experiments in combination with indoor simulations test. The relationship between grouting parameters and their influencing factors is mainly studied. The more famous grouting parameter simulation tests include: anhydrous porous media permeability test, permeability grouting test in fractured rock mass, water blocking test under dynamic water conditions, saturated porous media permeability test, particle filterability test in permeability grouting, Porous media grouting simulation test, test on the influence of slurry viscosity on pressure distribution, water displacement test under hydrostatic conditions, grouting simulation test research in sand and pebble (gravel) layer, and grouting permeability simulation test, etc.

2. Simulation experiments. Due to the significant difference between the simulation conditions and the actual geological structure, simulation parameters such as cracks, void state parameters, and medium particle size are difficult to match with the actual conditions, and often only a single crack can be simulated. Therefore, the flow characteristics and laws of the simulated chemical grouting slurry differ greatly from the actual situation. The future development direction is to further simulate and simulate to narrow this gap and guide specific grouting engineering practices.