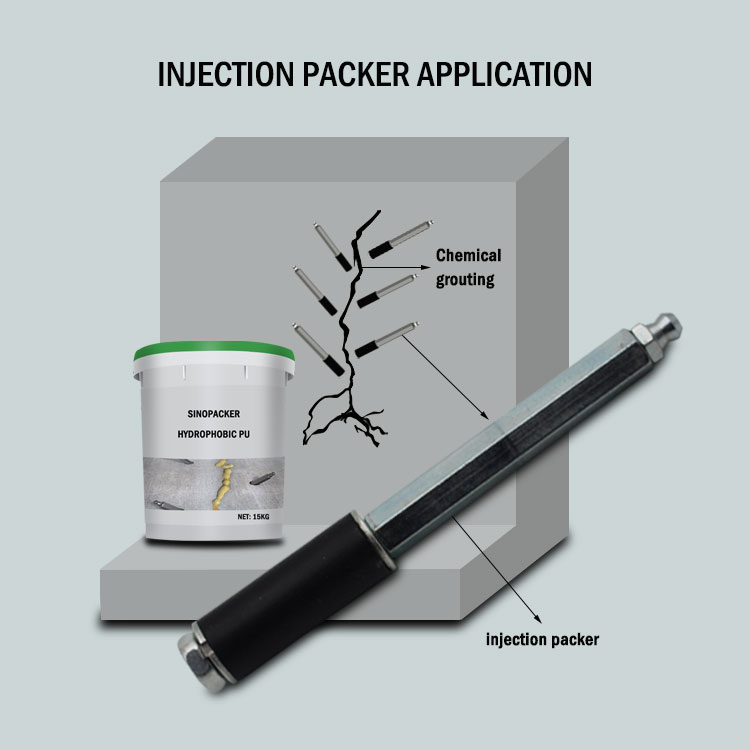

What is injection packer

Injection packer is a device for chemical materials grouting, which is composed of grease connector, rubber pipe and packer body. The injection packer is widely used in waterproofing projects, especially chemical grout engineering, such as polyurethane and epoxy resin injection.

The principle is to use the continuous high pressure generated by the grouting machine to inject the chemical materials into the concrete gaps. When the slurry encounters the water in the concrete cracks, it will quickly disperse, emulsify, expand, and consolidate. In this way, the consolidated elastomer fills all the cracks in the concrete and completely blocks the water flow outside the concrete structure to achieve water-stopping and leak-proofing.

High-pressure grouting injection is the most popular waterproofing and leak stop technology in the world. With the further improvement of production technology, injection packer will be used in more fields, and the quality will be more better.

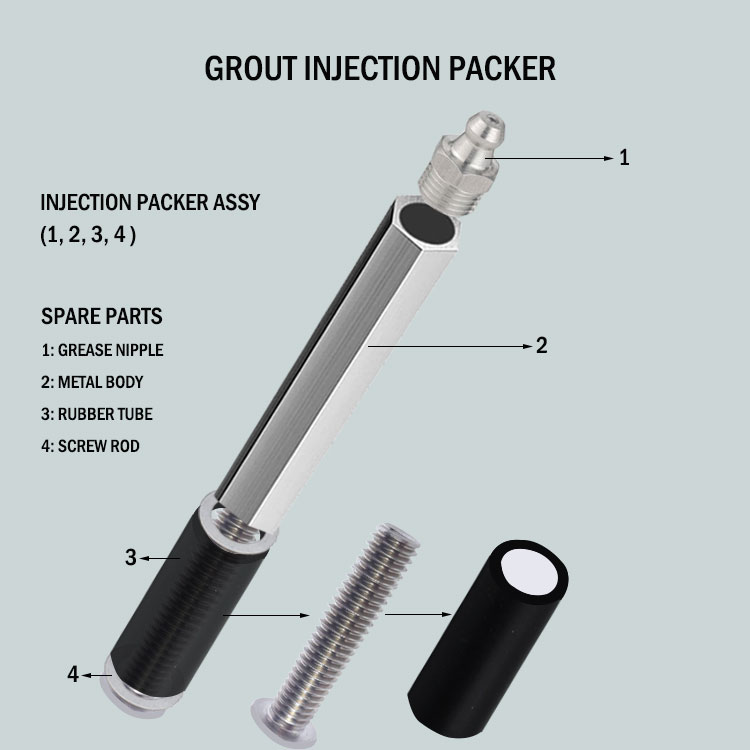

Composed Part

There are many injection packer shapes, but the component parts are basically the same. Usual, a injection packer is composed of grease nipple, rubber tube, packer body, spacer etc.

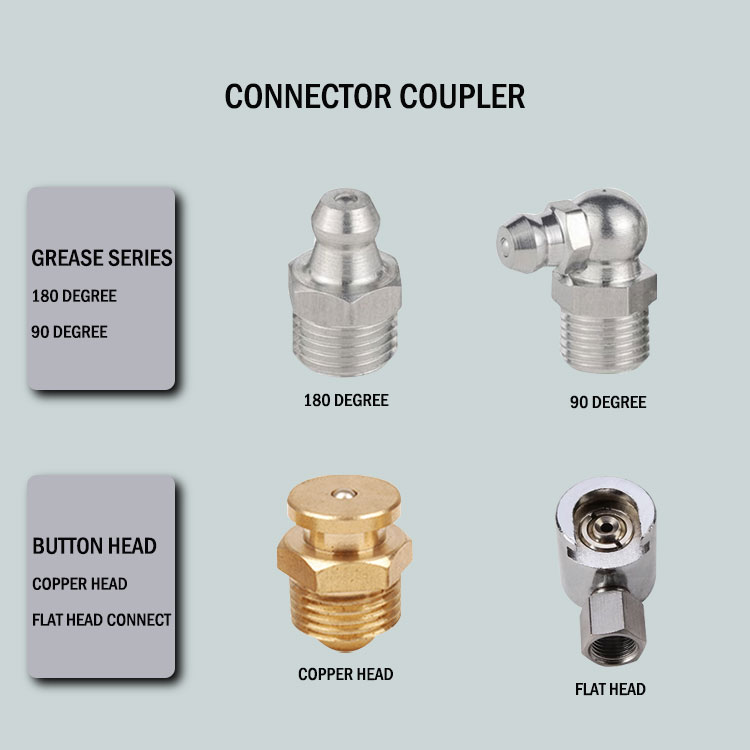

Grease nipple

Grease nipple is key part connector for injection packer and high pressure grout pump. Grease nipple is made of Nickel plated steel, which have good ductility and toughness, high mechanical properties and corrosion resistance. One way ball in the nipple effectively prevent PU from flowing back.

Main size have M6, M8, M10. Also support button head nipple.

| Item | distance Teeth | Thread length | Hexagon | Length |

| M6*1 | 1 | 5.6 | 8 | 14 |

| M8*1 | 1 | 7 | 10 | 16.2 |

| M10*1 | 1 | 7.4 | 11 | 18 |

| M12*1.25 | 1.25 | 9.5 | 14 | 21.5 |

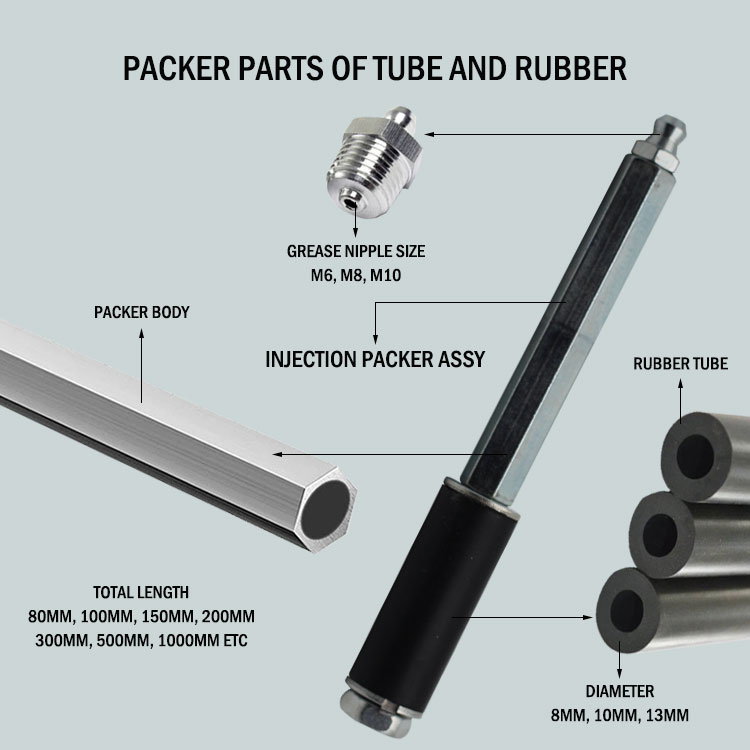

Packer body length

For the injection working, chose the right length of injection packer is an important thing. Also the wear resistant body act as a support after grout injection operation. Our packer metal body length from 80mm to 1000mm. Usual, half the thickness of the concrete is selected as the standard. For example, the concrete thickness 300mm, and the injection packer 150mm is ok. Following our packer length for review.

| Shape | Diameter | Length |

| Hexagon, rod tube | 10mm, 13mm, 16mm | 80mm ~ 1000mm |

Rubber Tube

The quality of rubber determines whether the injection packer is stable in the hole. Sinopacker rubber is soft and highly elastic, so that make sure the PU foam not leakage. Following is rubber tube data sheet and features.

Tensile Strength |

Tear Strength |

Elongation |

Hardness |

Compression Set |

Heat resistance strength |

5-25 Mpa |

40 KN/m |

300~ 700% |

70 ~80 |

40% |

130 ℃ |

Brand

Sinopacker is China top injection packer manufacturer since 2017, and has more than 80 advanced production machines. These high-precision and high-efficiency equipment ensure the consistency and stability of injection packer.

Sinopacker always adhered to the principles of technological innovation and quality first, and the product series is widely, including but not limited: aluminum, steel, plastic, button head, brass screw, removable, copper, surface adhesive injection packer.

Sinopacker’s injection packers are designed to withstand the toughest conditions and provide reliable performance, making them the preferred choice for many waterproofing applications. With an annual output of over 10,000,000 pieces, we can provide fast delivery to ensure your project stays on schedule.

With excellent product quality and perfect after-sales service, Sinopacker has won a high reputation in the concrete repair and waterproofing materials market.

Injection packer series

Injection packer is just a grouting accessory and has nothing to do with the waterproofing effect. The quality of the chemical grouting materials determines the waterproofing effect. Today, different countries use different injection packer, I will introduce you to the categories.

Materials and length

According to materials, there are aluminum packer, steel packer, plastic packer, copper packer etc. Aluminum, steel packer have rubber tube, which play a stabilizing role with expansion in the drill hole. Plastic injection packer is simple shapes that can be easily knocked in with a hammer.

According to the packer length, there are normal length packer, long injection packer. Usual, 80mm, 100mm, 150mm is normal length for using. For deep injection, it should chose long injection packer, such as 200mm, 300mm, 500mm injection packer. For grout injection works, it does't matter whether with short or long packers. If can be waterstop, the operation is the right choice.

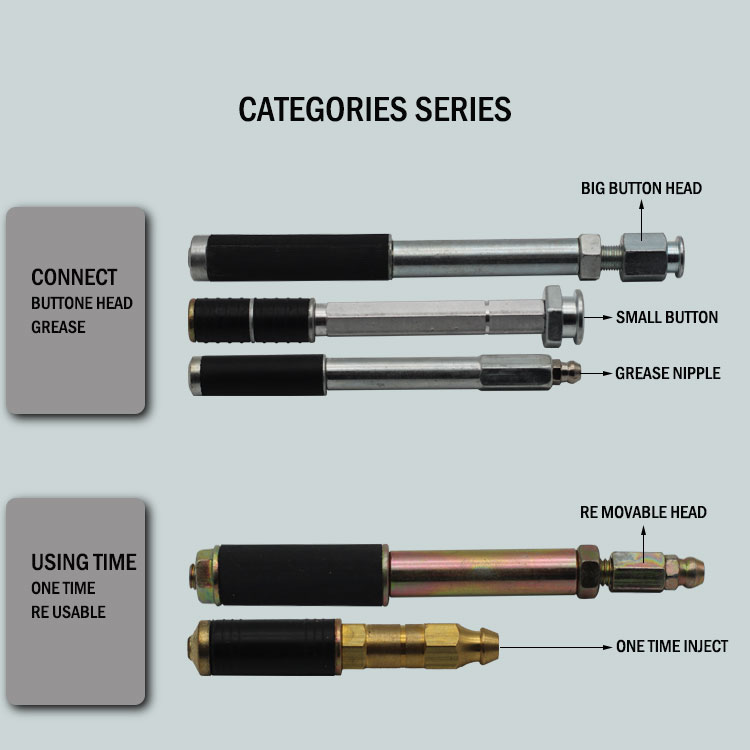

Connection and using time

According to connection, there are button head packer, 90D gree grease nipple packer, 45 Degree injection packer. Choose different injection packer according to different waterproofing projects.

According to pressure of nipple, there are low pressure packer, high pressure injection packer. The temperature and the viscosity of the chemical grout materials will affect the injection packer choice. In cold areas, low pressure injection packer are chosen. On the contrary, choose high pressure injection packer in hot country.

According to the injection time, there are one time injection packer, re usable injection packer with removable head.

Of course, every country and region has usage habits with injection packer. Just like those who use Apple IOS system not familiar with Android system.

Injection packer is just a grouting accessory and has nothing to do with the waterproofing effect. The quality of the chemical grouting materials determines the waterproofing effect.

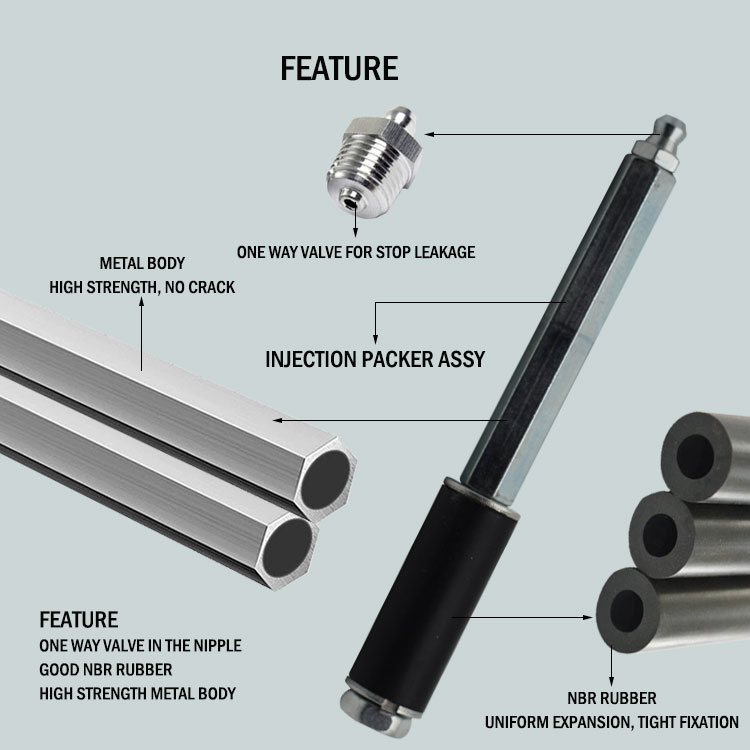

Feature

As an important grouting auxiliary accessory, the grout injection packer has the characteristics of high quality and stable performance. The following are the featured performances.

The grease nipple is equipped with a one-way valve to prevent the chemical grout from spraying back under high-pressure pushing, avoiding wastage of grouting materials.

With the development of chemical grouting materials, construction operation is not restricted by season and can be used for various waterproofing projects, including maintenance and emergency repair projects.

Strong adaptability and can grout a variety of chemical materials, including Polyurethane foam, epoxy resin, acrylic gel.

Multiple model types to adapt to different construction needs. From the short to long, from aluminum to steel, from surface adhesive to removable packer.

Connector

In order to realize the grouting injection engineering project, the coupler head is an indispensable accessory for injection packer. To match different grease nipple, different connector is required. There are main two series of coupler connector.

Button head connector apply for flat head injection packer. For large flow chemical injection, it need button head injection packer. And button head have good seal when inject.

High pressure connector match for grease nipple. The grease nipple head connect fast, and the cost is low when using. The 4 jaw grease nipple tighten the connector and seal good when inject.

The Sinopacker have multiple coupler connector models to apply for different grease nipple. In high-pressure grouting, good quality explosion-proof coupler must be selected to prevent danger.

Also Sinopacker can offer 90 Degree grease nipple and copper head for special operation.

Application

Grout injection packers are an indispensable accessory and parts in the chemical grouting field. The injection packer can be connected with high pressure grout pump, also apply with acrylic gel pump equipment.

- Waterproofing and leakage stop in tunnel, culvert,subway, basements, underground garages.

- Concrete crack and epoxy injection for concrete repair.

- Grout injection for Reservoirs, dams, hydroelectric power stations and other water conservancy projects.

- Grout injection for airports, ports and other large engineering project.

- Curtain injection and wall crack repair.

- Polyurethane foam, acrylic gel and epoxy injection for other waterproof project.

For injection waterproof project, it is no problem together with hydrophobic, hydrophilic polyurethane foam. Together with the injection hose and the waterstop, the waterproof effect is better.

Tip of injection packer operation

Find out the crack: Check the on-site construction conditions, analyze the causes of water leakage, and find out the width, length, depth and penetration of the leaking parts, and cracks. Then Clean concrete crack surface.

Drill the hole: According to the thickness of the concrete structure, drill holes at an angle of 5cm to 10cm at the crack, from low to high, with a hole spacing of 25cm to 30cm. The size of the hole should be determined according to the size of the matching injection packer. The cross sections of holes and cracks should intersect at an angle of 30 to 50 degrees.

Put the packer in the hole. The location and number of grouting holes need to be reasonably arranged according to different leakage conditions.

Inject pouring. Pour chemical material into drill holes.

Finished the grouting injection. When checking that there is no leakage, remove the grouting head and fill the hole with cement mortar and other materials.

Development

Due to the demand for waterproofing in modern buildings, grouting technology has been greatly developed.

Automated production: High work efficiency and improve enterprise production efficiency; The entire production process is stable and the consistency of the product is improved.

Environmental: Injection packer have automated production and implement low-carbon environmental protection policies, saving resources and improving efficiency.

Serialization with more variety series. As there are more and more waterproofing projects and the injection packer application fields become more and more segments.

Complete sets and standardization. High-performance injection packer is the main accessories for implementing chemical grouting operations.

Sinopacker research and development has never stopped, and injection packer has now become a distinctive and indispensable advanced tools in modern engineering.